TUFF ANGLE EDGE PROTECTORS PATENT

Understand the Characteristics of Tuff Angle Edge Protector

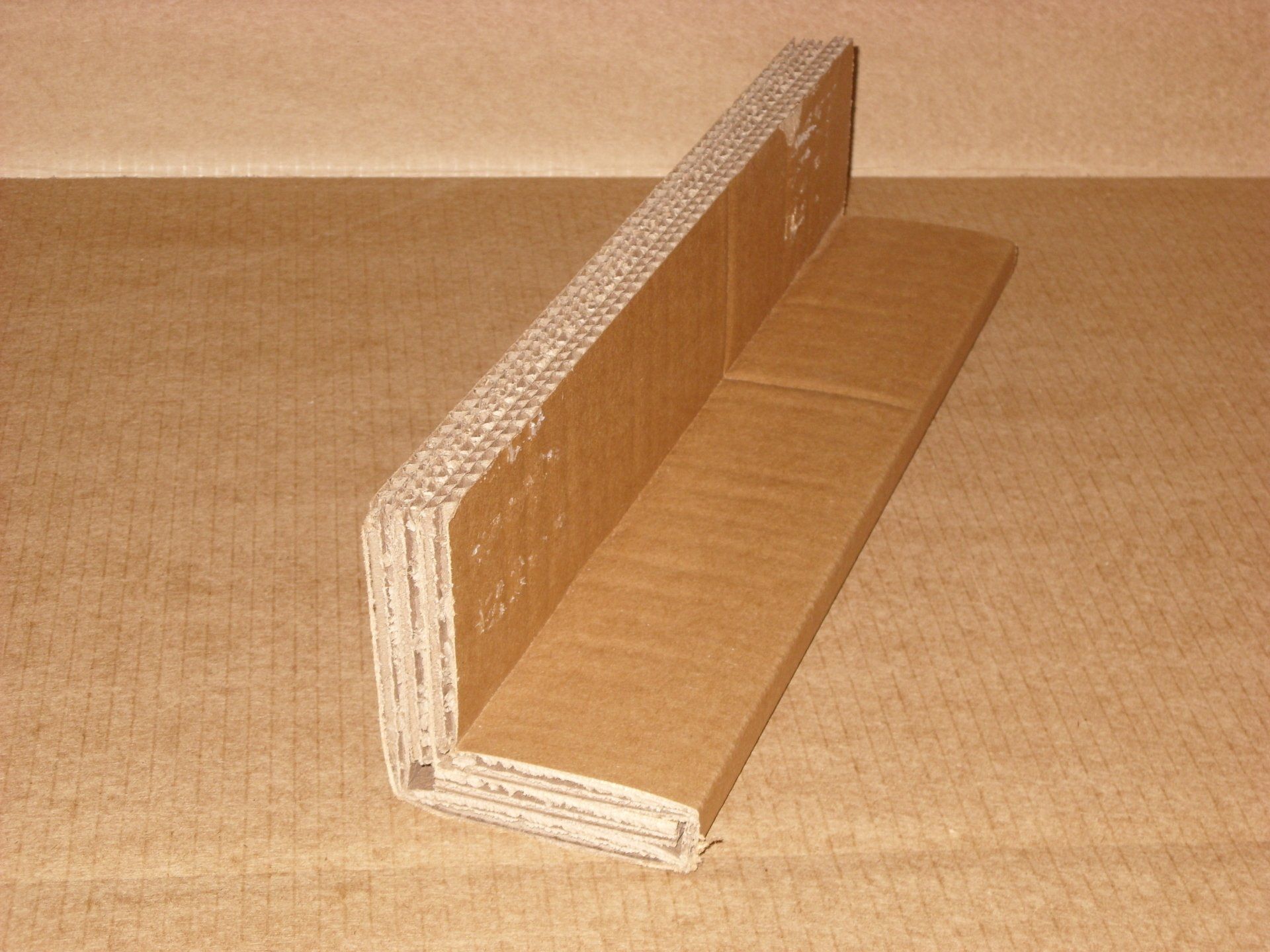

The patented construction of Tuff Angle edge protectors give them a combination of characteristics that traditional edge protectors simply cannot match. Tuff Angle edge protectors are made from corrugated sheets that are scored, glued, folded, and held in a ninety degree shape until dry. They are nested for shipment and arrive at the customer preformed and ready to use. The scoring and folding is like a trifold wallet. All three layers, once glued, are bent one more time into a ninety-degree angle. This patented folding design gives tremendous strength to the corner of the protector, one of the most critical areas for product damage. This is a significantly different process than is used to make traditional corner boards. Most edge protectors are formed simply by layering flat or fluted paper until a desired thickness is created, and then plunging the layers into a V shape.

The patented triple layer/triple fold process used to construct Tuff Angle edge protectors make them more impact resistant than other options. Their reinforced corners, cushioning, and stacking strength unite to make them more versatile than other edge protectors. Naturally strong, corrugation direction and paper grades can be engineered for multiple stacking of heavy loads in the truck, or in the warehouse. Tuff angle edge protectors are environmentally friendly and engineerable for task unheard of by other corner boards.